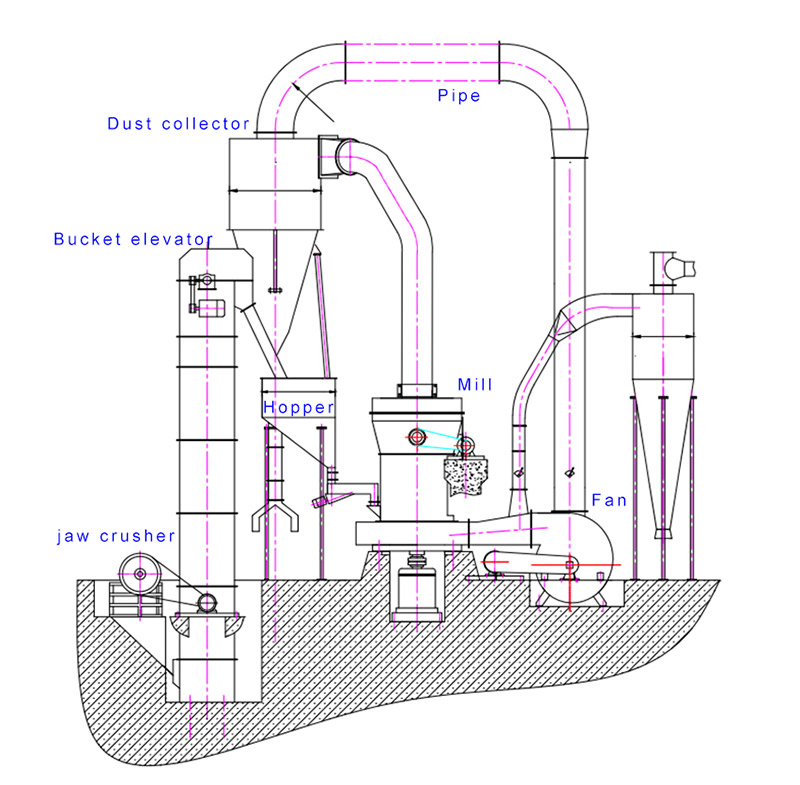

Powder Making Grinding Mill Raymond Mill Machine

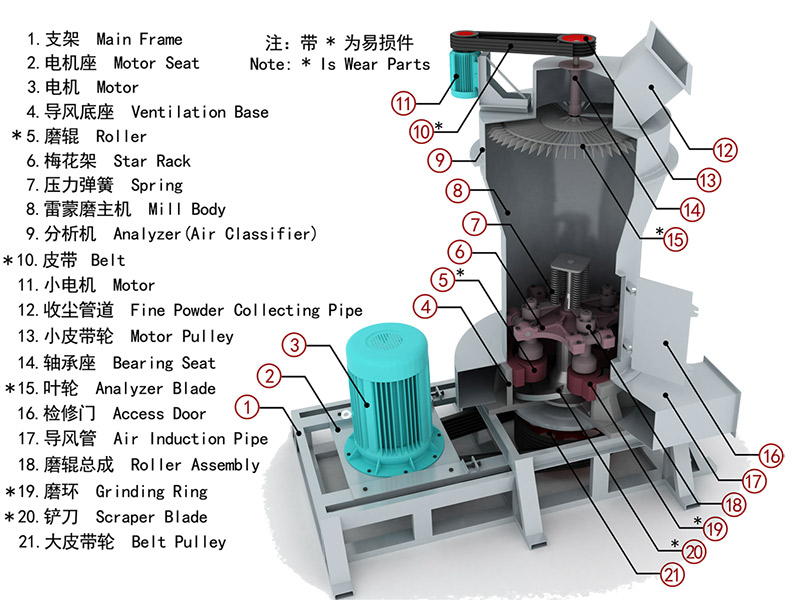

Raymond mill grinding machine is a system including the crusher, feeding, and grinding,classifying.The structure of the grinding mill machine is mainly composed of main machine, analyzer, fan, finished cyclone separator, micro powder cyclone separator and air duct. The main engine is composed of frame, air inlet volute, blade, grinding roller, grinding ring and cover. Besides,the main wearing parts of raymond mill are grinding roller and ring and the lifting shovel. All of them are made of high wearable high manganese alloy Mn13Cr2.

Working Principle

Firstly, raw material is crushed by jaw crusher to the required size of Raymond mill, which is lifted up to the hopper. Secondly, the raw material goes into the grinding chamber through the vibrating feeder at an even rate. Thirdly, the raw material lifted by the shovel is ground into powder between the ring and roller. Fourthly, the powder is blown up to the cyclone collector through the classifier, which will be collected through the discharging valve. The unneeded powder, which cannot go through the classifier, will be reground into the needed powder.

Specification

|

Model |

Roller Number |

Roller Size (mm) |

Feeding Size (mm) |

Output Size (mm) |

Capacity (T) |

Motor Power (kw) |

Weight (t) |

|

3R1510 |

3 |

150*100 |

15 |

0.2-0.044 |

0.3-1.2 |

7.5 |

2 |

|

3R2115 |

3 |

210*150 |

15 |

0.2-0.044 |

0.4-1.6 |

15 |

3.6 |

|

3R2615 |

3 |

260*150 |

20 |

0.2-0.044 |

0.8-2.5 |

18.5 |

4.2 |

|

3R2715 |

3 |

270*150 |

20 |

0.2-0.044 |

0.9-2.8 |

22 |

4.8 |

|

3R2715 |

3 |

300*150 |

20 |

0.2-0.044 |

1.2-3.5 |

30 |

5.3 |

|

4R3016 |

4 |

300*160 |

20 |

0.2-0.044 |

1.2-4 |

30 |

8.5 |

|

4R3216 |

4 |

320*160 |

25 |

0.2-0.044 |

1.8-4.5 |

37 |

15 |

|

5R4121 |

5 |

410*210 |

30 |

0.2-0.044 |

3-9.5 |

75 |

24 |

Raymond Mill Advantages

1.Higher output. Our Raymond mill’s output increases by 10%-20% comparing under the same power condition.

2. Larger range of final fineness. Size of final product is between 0.2mm –0.044mm (40-400mesh).

3. Good dust control. Our machine meets the requirement of national dust-dump standard.

4. Easy to operate. The whole system is combined by some independent systems, and the cohesion between the systems is good.

5. Excellent sealing. The lapping device adopts the multi-stage seal of superimposed type, which has good sealing performance.