1100 1200 Model Gold Wet Pan Mill Machine In Africa

Wet pan mill is a popular gold and silver ore grinding machine in Africa and South America countries, because of its low investment, easy use and maintenance, and quick cost recovery. The most common way is to put mercury in the wet pan mill, and mix the gold particle with the mercury, which is called Amalgamation. Then the mixture of gold and mercury can be put into crucible for high temperature heating. During this process, the mercury is evaporated and pure gold is left in the crucible.

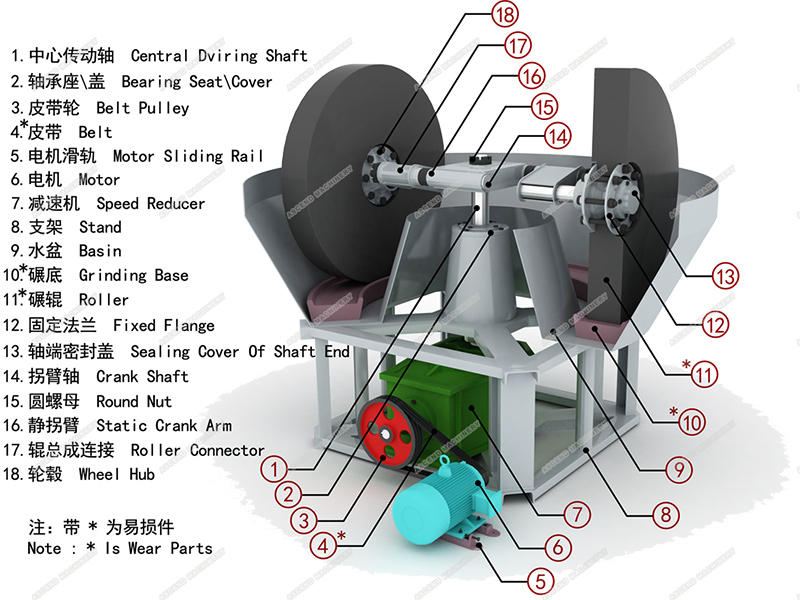

Wet Pan Mill Working Principle

This equipment adopts the working mode of wheel-driven grinding: firstly, the motor drives the power to the reducer, and under the drive of the reducer, the torque is transferred to the horizontal shaft abovethrough the big vertical shaft, and then the torque is transferred to the roller through the pull rod installed on both ends of the horizontal shaft, so that the roller generates driving force and rotates counterclockwise along the horizontal axis.The roller can rotate around the big vertical axis of the wet roller and rotate around the center axis of the roller.The added mineral material is crushed thoroughly after repeated extrusion, kneading and grinding by the extrusion pressure brought by the weight of the roller itself and the huge friction generated by the roller during its revolution and rotation.

Wet Pan Mill Specification

| Model | Type(mm) | Max feed size(mm) | Capacity(t/h) | Power(Kw) | Weight(ton) |

| 1600 | 1600x350x200x460 | <25 | 1-2 | Y6L-30 | 13.5 |

| 1500 | 1500x300x150x420 | <25 | 0.8-1.5 | Y6L-22 | 11.3 |

| 1400 | 1400x260x150x350 | <25 | 0.5-0.8 | Y6L-18.5 | 8.5 |

| 1200 | 1200x180x120x250 | <25 | 0.25-0.5 | Y6L-7.5 | 5.5 |

| 1100 | 1100x160x120x250 | <25 | 0.15-0.25 | Y6L-5.5 | 4.5 |

| 1000 | 1000x180x120x250 | <25 | 0.15-0.2 | Y6L-5.5 | 4.3 |

Wet Pan Mill Spare Parts

The wet pan mill major spare parts include motor,gearbox, gearbox shaft, belt pulley,roller and ring,v belts,etc.

Wet Pan Mill Delivery

Usually, one 20 GP container can take 5 set complete 1200 wet pan mills or 1100 wet pan mills. One 40 GP container can take 16 set pan mill without roller and rings.