1400 1500 1600 Gold Wet Pan Mill Chilean Mill For Zimbabwe And Sudan

The gold wet pan mill machine has different models with different capacities. The small model is 1100 and 1200 model,which is usually used in Sudan, Egypt,Mauritania and Niger. The big capacity includes 1400,1500 and 1600 model, which is popular in Zimbabwe. And the big wet pan mill machine is usually used together with the jaw crusher, gold concentrator or gold kacha concentrator.The big wet pan mill capacity is much higher than the 1100 and 1200 model, for instance, the 1500 wet pan mill machine capacity can reach nearly 2 ton per hour.

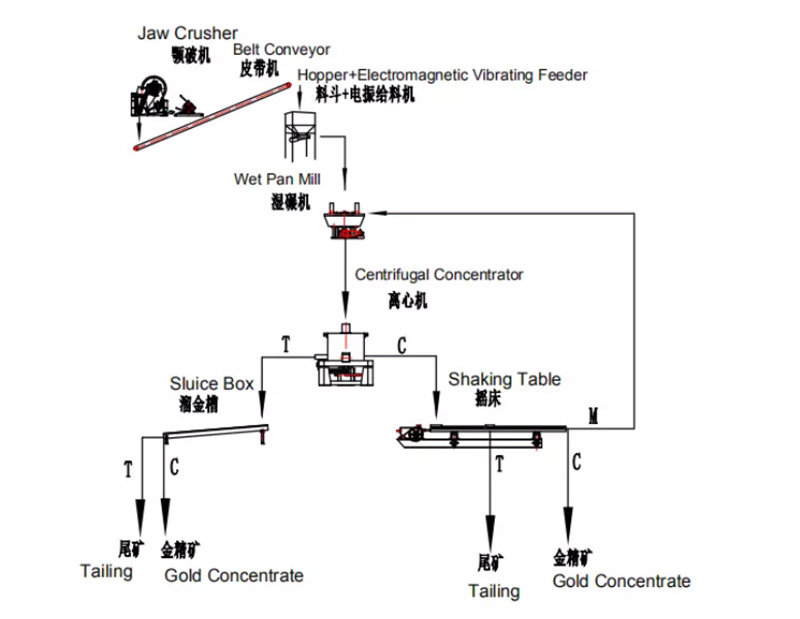

Wet Pan Mill Gold Mining Solution

The stone is put into the jaw crusher, and the stone is crushed into less than 20mm small particles. Then the stone particles is transmitted into the gold wet pan mill machine. The slurry made by the wet pan mill is transferred into the gold concentrator, in which some gold concentrate is kept in the grooves of the concentrator. The tailing from the concentrator goes to the shaking table, and some remaining gold can be further recovered by the gold shaking table.

Wet Pan Mill Specifications

|

Model |

Specifications |

Input size |

Rotate speed |

Capacity |

Power |

Machine weight |

|

1600A |

1600×400/2100×500*180±20mm |

<30mm |

18-20 |

5-6T/H |

37KW |

16.3 |

|

1500A |

1500×400/2100×500*180±20mm |

<30mm |

18-22 |

4-5T/H |

30KW |

13.5 |

|

1500B |

1500×350/2050×450*150±20mm |

<30mm |

18-22 |

4-5T/H |

22KW |

12.3 |

|

1500C |

1500×300/2050×400*150±20mm |

<30mm |

18-22 |

4-4.5T/H |

22KW |

11.3 |

|

1400B |

1400×250/2050×350*150±20mm |

<30mm |

18-22 |

3-4T/H |

15kw |

8.5 |

|

1400A |

1400×300/2050×400×150±20mm |

<30mm |

18-21 |

3-4T/H |

18.5kw |

9.6 |

|

1300B |

1300×250/2000×350×150±20mm |

<30mm |

18-22 |

2.5-3.5T/H |

11kw |

7.5 |

|

900A |

900×170/1700×220×45±10mm |

<30mm |

11-13 |

0.1-0.5T/H |

3kw |

2.9 |

|

900B |

900×140/1700×170×45±10mm |

<30mm |

11-13 |

0.1-0.5T/H |

3kw |

2.6 |

|

1200A |

1200×200/1800×250×100±10mm |

<30mm |

11-19 |

2-3T/H |

7.5kw |

5.5 |

|

1200B |

1200×180/1800×250×100±10mm |

<30mm |

11-19 |

2-3T/H |

5.5kw |

5.5 |

|

1100A |

1100×200/1800×250×100±10mm |

<30mm |

11-19 |

1-2T/H |

7.5kw |

5 |

|

1100B |

1100×180/1800×250×80±10mm |

<30mm |

11-19 |

1-2T/H |

5.5kw |

5 |

|

1000 |

1000×200/1800×250×80±10mm |

<30mm |

11-19 |

0.5-1T/H |

5.5kw |

4.5 |

Wet Pan Mill Delivery