Magnetic Separator

There are many minerals that can be separated by the magnetic separator, such as magnetite, limonite, hematite, manganese siderite, ilmenite, wolframite, manganese ore, manganese carbonate ore, manganese ore, manganese oxide ore, iron ore, kaolin, rare earth ore, etc., which can be separated by the magnetic separator.

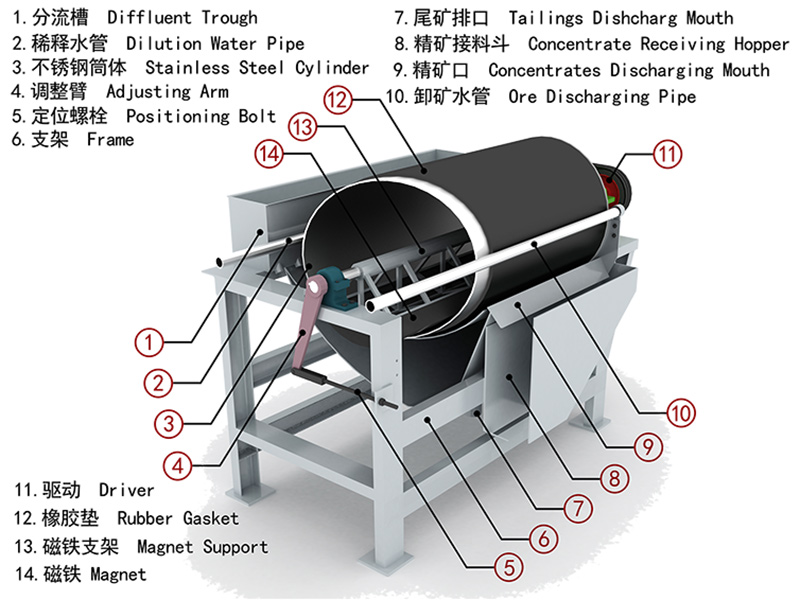

Working Principle

The pump enters into the mining area of the cell though ore box with the force of water flow. Magnetic particles form into magnetic ball or linkage with the force of magnetic field. The magnetic ball and linkage are absorbed on the drum during they are moving towards magnetic pole with the magnetic force. When the magnetic ball and linkage are rotating with the moving drum, because of alternating polarity and magnetic stirring, the gangue and other non magnetic ore mixed in magnetic ball and linkage is fall down, while magnetic ball and linkage are absorbed on the surface of the drum. These are concentrates we need. The concentrates come to the field where the magnetic is the weakest with the rotating drum. Then they fall in to concentrate slot by the water flow. But the full magnetic roller uses brush roll to discharge ores. At last, the non-magnetic or weak magnetic minerals are discharged out of the cell with plump.

Product Advantages

1. Good separation effect:This machine adopts dynamic magnetic system. The raw ores slide, move and roll at the surface of the drum, and there is no ores sticking to the drum, which helps separate different ores. The grade can be improved 1-4 times in the first separation process, and the grade can reach 60% in fine separation process.

2. Large capacity:By using wrapped type open magnetic system, the materials do not stick together and the blocking phenomenon can be avoided, which leads to large capacity. The feeding capacity of an individual magnetic separator is at least 50 tons. And the machines can connected together to be put into use so as to improve the capacity.

3. Wide application:This type magnetic separator can be divided into 4 categories, more than 20 types and models, which can meet the needs of iron ore, river sand, tailings, slags, steel ash, sulfate slag, grinding materials, refractory, plating, rubber, food industries and etc. Some of them are with multi-purposes.

Specifications

| odel | CTB612 | CTB618 | CTB7512 | CTB7518 | CTB918 | CTB924 | CTB1018 | CTB1024 | |

| Diameter(mm) | Φ600 | Φ600 | Φ750 | Φ750 | Φ900 | Φ900 | Φ1050 | Φ1050 | |

| Length (mm) | 1200 | 1800 | 1200 | 1800 | 1800 | 2400 | 1800 | 2400 | |

| Speed (r/min) | 35 | 35 | 35 | 35 | 20 | 20 | 20 | 20 | |

| Gauss | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | 1200-1500 | |

| Feeding size (mm) | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | 0-0.4 | |

| Feeding density(%) | 20-25 | 20-25 | 20-25 | 20-25 | 25-35 | 25-35 | 25-35 | 25-35 | |

| Work clearance(mm) | 30-40 | 30-40 | 30-40 | 30-40 | 45-75 | 45-75 | 45-75 | 45-75 | |

| Capacity | dry ore (t/h) | 10-15 | 15-20 | 15-20 | 30-35 | 35-50 | 40-60 | 50-100 | 70-130 |

| pulp (m3/h) | 10-15 | 15-20 | 15-20 | 30-35 | 100-150 | 120-180 | 170-120 | 200-300 | |

| Power (kw) | 2.2 | 2.2 | 2.2 | 3 | 4 | 4 | 4 | 5.5 | |

| Weight (kg) | 1200 | 1500 | 1830 | 2045 | 3500 | 4000 | 4095 | 5071 | |

| Overall dimension (mm) |

2280×1300 ×1250 |

2280×1300 ×1250 |

2256×1965 ×1500 |

2280×1965 ×1500 |

3000×1500 ×1500 |

3600×1500 ×1500 |

3440×2220 ×1830 |

3976×2250 ×1830 |

|