Gold Ore Ball Mill Grinding Spiral Classifier Machine

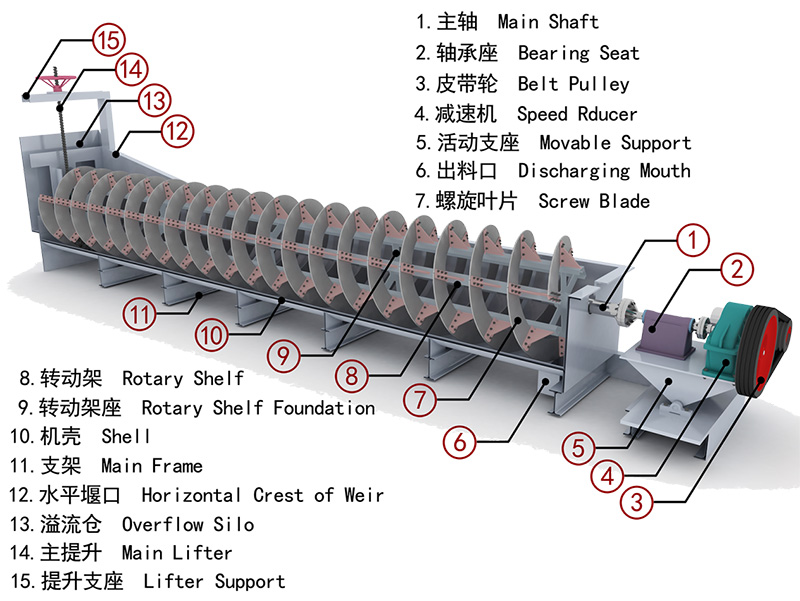

The classifier of our company is mainly composed of transmission device, screw body, tank body, lifting mechanism, lower support (bearing bush) and ore discharge valve. The classifier produced by our company adopts advanced technology research and development, featuring simple structure, reliable work, convenient operation, etc.

Working Principle

When the machine is working, the classifier is based on the principle of different solid particle size and specific gravity, so the settling speed in the liquid is different. Fine ore particles float in the water and overflow, and coarse ore particles sink at the bottom of the tank. A classification equipment that pushes the screw to the upper part to discharge for mechanical classification. It can grade the material and powder grinded out of the mill to filtration, and then screw the coarse material into the mill feed port by using the spiral slice spiral disc to discharge the filtered fine material from the overflow pipe. The base of the machine is made of channel steel and the body is welded with steel plate. The screw shaft’s water head, shaft head, adopt pig iron sleeve, wear-resistant and durable. The lifting device is divided into electric and manual.

Specifications

|

Model |

Diameter of screw |

Speed of screw |

Capacity(t/d) |

Slop(º) |

Driving |

Lifting motor |

Dimension |

Weight |

|||

|

Returned |

Overflow |

Model |

Power |

Model |

Power |

||||||

| FLG-508 | 508 | 8-12 | 140-260 | 32 | 14-18 | Y90L-6 | 4 | / | / | 5340x934x1274 | 2.8 |

| FLG-750 | 750 | 6-10 | 250-570 | 65 | 14-18 | Y132S-6 | 5.5 | / | / | 6270x1267x1584 | 3.8 |

| FLG-915 | 915 | 5-8 | 415-1000 | 110 | 14-18 | Y132M2-6 | 7.5 | / | / | 7561x1560x2250 | 4.5 |

| FLG-1200 | 1200 | 5-7 | 1165-630 | 155 | 17 | Y132M2-6 | 7.5 | Y90L-4 | 1.5 | 7600x1560x2250 | 7.0 |

| FLG-1500 | 1500 | 2.5-6 | 1830-2195 | 235 | 17 | Y160M-6 | 11 | Y100L-4 | 2.2 | 10200x1976x4080 | 9.5 |

| FLG-2000 | 2000 | 3.5-5.5 | 3890-5940 | 400 | 17 | Y160L-4 | 15 | Y132S-6 | 3 | 10788x2524x4486 | 16.9 |

| 2FLG-1200 | 1200 | 5-7 | 2340-3200 | 310 | 12 | Y132M2-6 | 7.5x2 | Y100L-4 | 2.2 | 8230x2728x3110 | 15.8 |

| 2FLG-1500 | 1500 | 4-6 | 2280-5480 | 470 | 12 | Y160M-6 | 11x2 | Y100L-4 | 2.2 | 10410x3392x4070 | 21.1 |

| 2FLG-2000 | 2000 | 3.6-4.5 | 7780-11880 | 800 | 12 | Y160L-6 | 15x2 | Y100L-4 | 3 | 10788x4595x4486 | 36.4 |