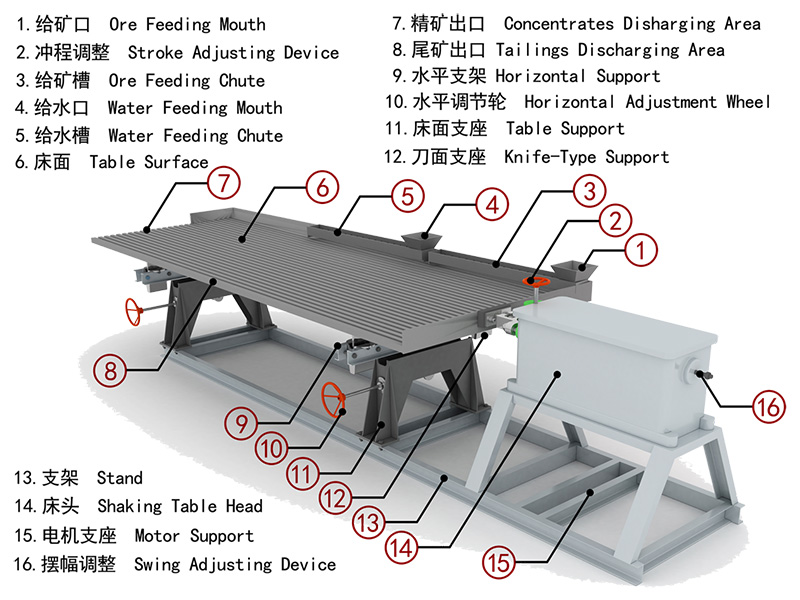

Gold Gravity Shaking Table Separator Machine

Shaking table which is one gravity separation machine can be widely applied in separating minerals, especially for separating gold and coal.Shaking table is mainly composed of bed head, electromotor, adjusting gradient device, bed surface, ore chute, water chute, rifle bar and lubricating system.It is widely applied in the classification of tin, tungsten, gold, silver, lead, zinc, iron, manganese, tantalum, niobium, titanium, etc.

Working Principle

The ore dressing process of the shaking table is carried out on the inclined bed surface with multiple strips. The ore particles are fed into the ore feeding trough at the upper corner of the bed surface, and at the same time the water is supplied by the water feeding trough for horizontal flushing. Therefore, the ore particles are stratified according to specific gravity and particle size under the action of inertia and friction force caused by the reciprocating asymmetric movement of the bed surface, and move longitudinally and incline along the bed surface of the shaking table The inclined bed surface moves laterally. Therefore, the ore particles with different specific gravity and particle size gradually flow from side a to side B in fan-shaped flow along their respective moving direction, and are discharged from different areas of concentrate end and tailings side respectively, and are divided into concentrate, medium ore and tailings. The shaker has the advantages of high ore ratio, high separation efficiency, easy care and easy adjustment of stroke. When the cross slope and stroke are changed, the running balance of the bed surface can still be maintained. The spring is placed in the box, the structure is compact, and the concentrate and tailings can be obtained in turn.

Specifications

|

Specification |

L-S(6-S) |

Water quantity (t/h) |

0.4-1.0 |

|

Stroke(mm) |

10-30 |

Surface size of table(mm) |

152×1825×4500 |

|

Times/min |

240-360 |

Motor(kw) |

1.1 |

|

Landscape angle(o) |

0-5 |

Capacity (t/h) |

0.3-1.8 |

|

Feed particle(mm) |

2-0.074 |

Weight (kg) |

1012 |

|

Feed ore density(%) |

15-30 |

Overall dimensions (mm) |

5454×1825×1242 |

Product Delivery