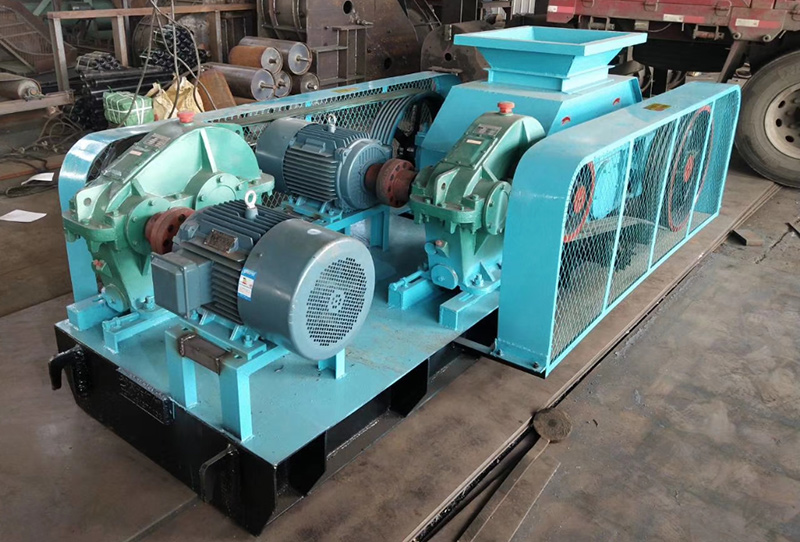

Smooth And Teeth Type Double Roller Crusher

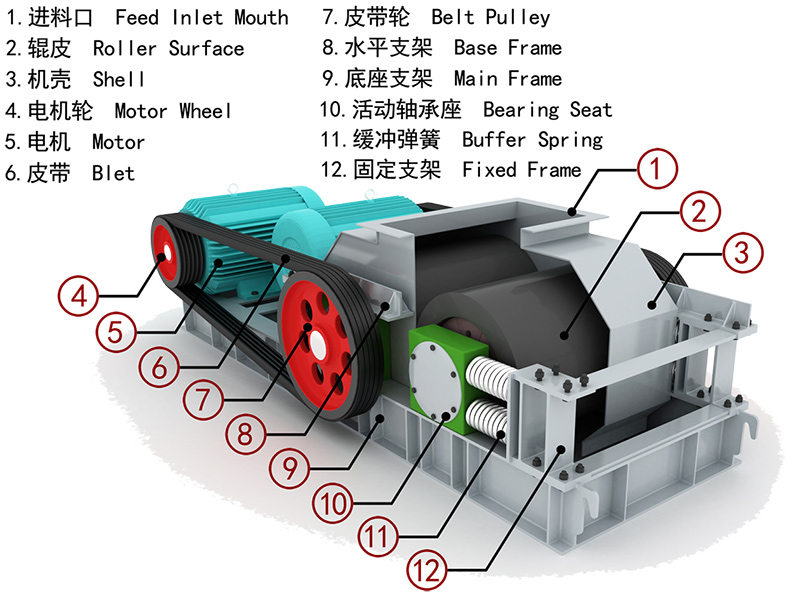

There are two cylindrical rollers horizontally installing on mutually parallel racks, where one of the roller bearing is movable and the other roller bearing is fixed. Driven by electric motor, the two rollers do opposite rotation, which produces downward acting force to crush materials between two crushing rollers; broken materials that are in line with the required size are pushed out by roller and discharged from the discharging port.

Working Principle of Double Roller Crusher

The crushed stone materials fall between two rollers through the feeding port for crushing, and the finished materials fall naturally. In case of hard or unbreakable materials, the roller can automatically retreat by the action of a hydraulic cylinder or spring, so as to increase the roller clearance and drop the hard or unbreakable materials, which can protect the roll crusher from damage. There is a certain gap between the two opposite rotating rollers. Changing the gap can control the product discharge particle size. A double roll crusher is to use a pair of opposite rotating round rolls, while an opposite roller crusher is to use two pairs of opposite rotating round rolls for crushing operation.

Besides producing the complete set of roller crusher, we also keep a large quantity of spare parts in the warehouse. The main wearing part of roller crusher is the roller plate, which is made of High manganese Mn13Cr2 alloy.

Specifications

| Model | Feeding size(mm) | Discharging granularity (mm) | Output

(t/h) |

Motor Power

(t/h) |

Dimensions(L×W×H) (mm) | Weight (kg) |

| 2PG-400*250 | <=25 | 2-8 | 5-10 | 11 | 1215×834×830 | 1100 |

| 2PG-610*400 | <=40 | 1-20 | 13-40 | 30 | 3700×1600×1100 | 3500 |

| 2PG-750*500 | <=40 | 2-20 | 20-55 | 37 | 2530×3265×1316 | 12250 |

| 2PG-900*500 | <=40 | 3-40 | 60-125 | 44 | 2750x1790x2065 | 14000 |

Advantages of Roller Crusher

1. Roller crusher can achieve the effect of more crushing and less grinding by reducing the particle size and improving the crushing characteristics of the material to be crushed. The crushed products are mostly cubes with less needle-like content and no tension or cracks.

2. The toothed roller of the roller crusher is made of high-yield wear-resistant material, which has a strong impact on-resistance and high wear resistance. It has the advantages of small loss and low failure rate when crushing materials, reducing the maintenance and maintenance costs in the later stage with low operation cost and long service life.

3. The roller crusher is equipped with an advanced mining machine concept, equipped with advanced environmental protection devices, and closed production. The whole production process has low noise, low dust, and low pollution, which meets the national environmental protection requirements.